Motion planning for mobile manipulators in multi-agent settings using MPC

Summary

Mobile manipulators, combining a robotic arm with a mobile base, are gaining traction in healthcare, logistics, and aerospace. While motion planning for single-agent systems is well-studied, multi-agent coordination remains a challenge, particularly in real-world settings. This thesis presents a decentralized Model Predictive Control (MPC) framework with a double integrator as dynamic model, denoted as MPC-d, MPC-d, for multi-mobile manipulators in shared workspaces. It integrates optimization-based planning and robust state estimation for collision avoidance, with a prioritized heuristic to mitigate livelocks. Simulations compare with a triple-integrator MPC (MPC-t) and Geometric Fabrics (GF), demonstrating comparable task success rates and superior efficiency. Real-world experiments confirm its effectiveness, showcasing reliable collision avoidance and improved coordination. Despite higher computational costs than reactive methods, MPC-d offers robust motion prediction and enhanced multi-agent performance.

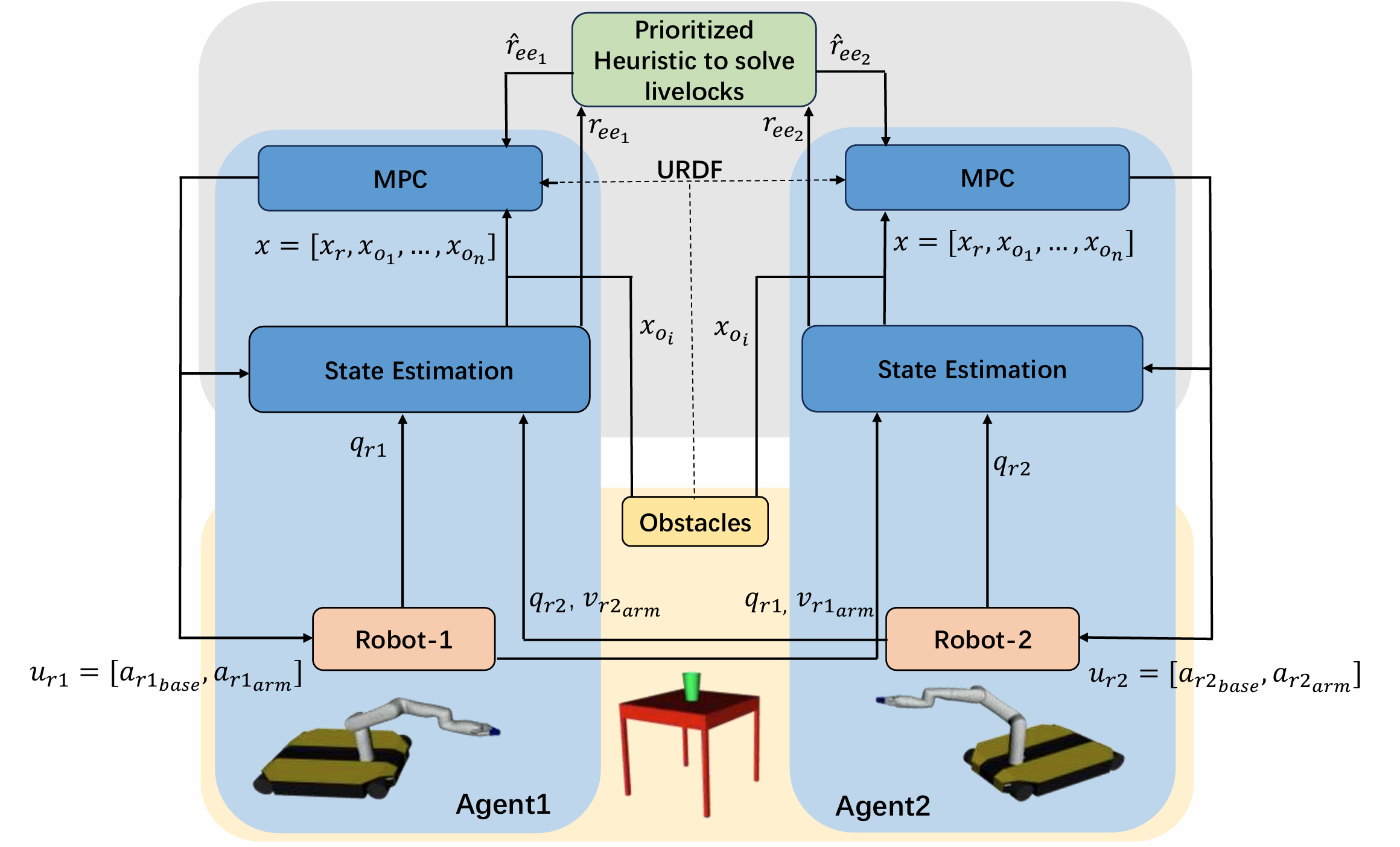

Overview

An Overview of the multi-robot MPC and a pioritized heuristic in a multi-agent settings

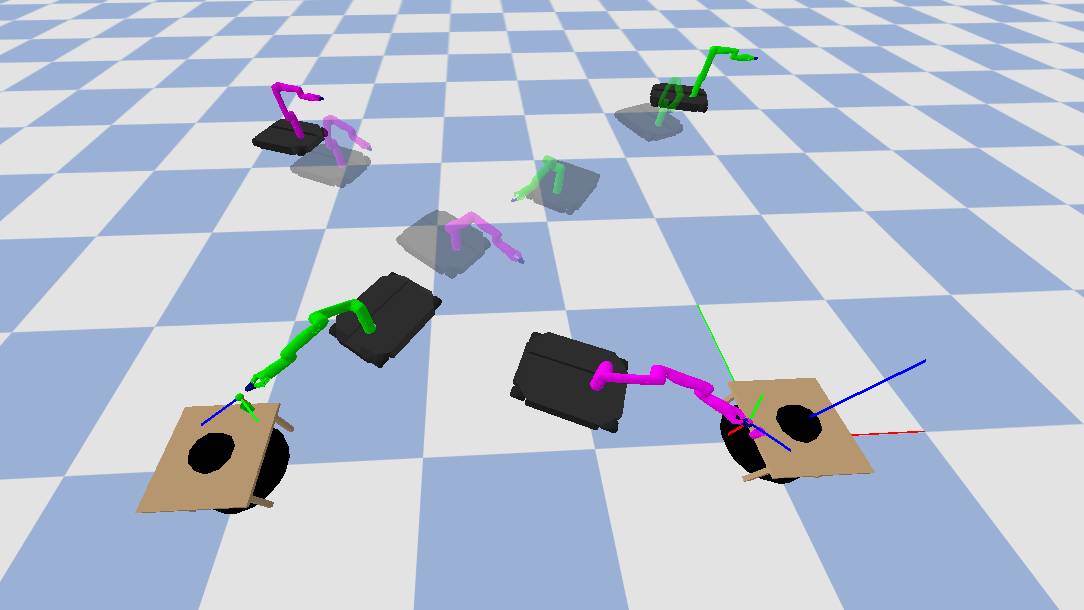

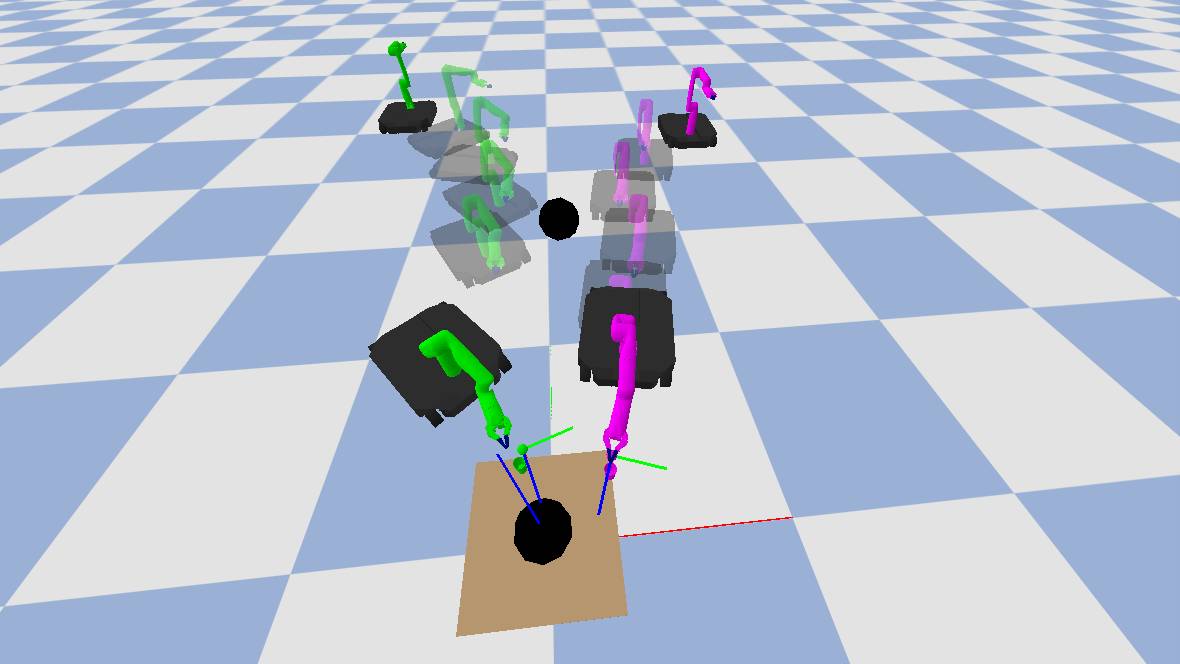

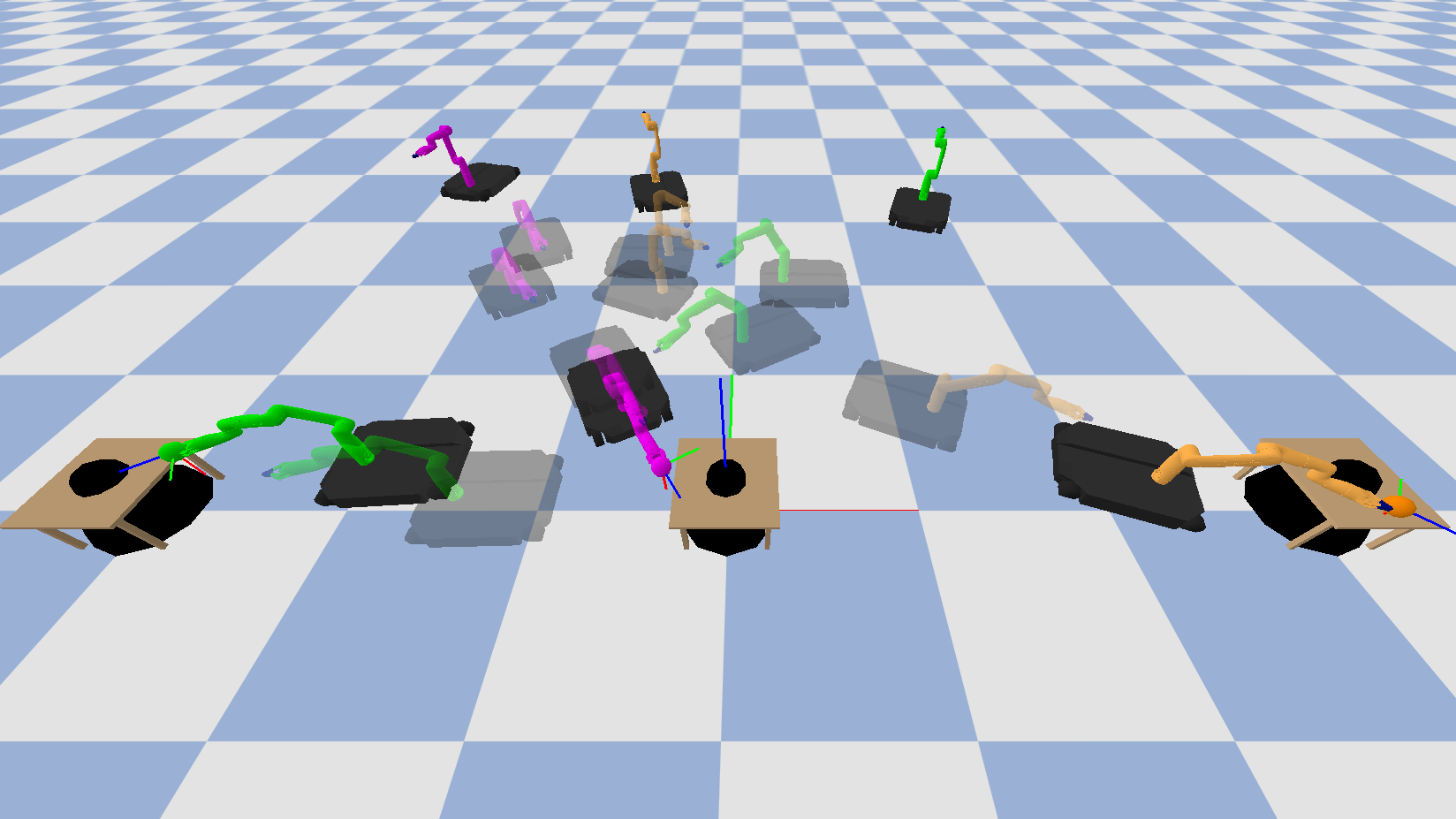

Simulation experiments

Simulated pick-and-place scenarios

(a) Scenario 1 (S1): Two tables

(b) Scenario 2 (S2): One table

(c) Scenario 3 (S3): Three robots

The proposed method is evaluated across three distinct realistic pick-and-place scenarios and compared against two baseline methods: GF and the original MPC-t approach.In each scenario, the robots' end-effector are required to reach a static pre-grasp target. The grasp target is represented by a marker placed next to the generated cup, whose color matches that of the corresponding robot's arm. The robots are tasked with achieving their targets while avoiding collisions with each other and static obstacles.

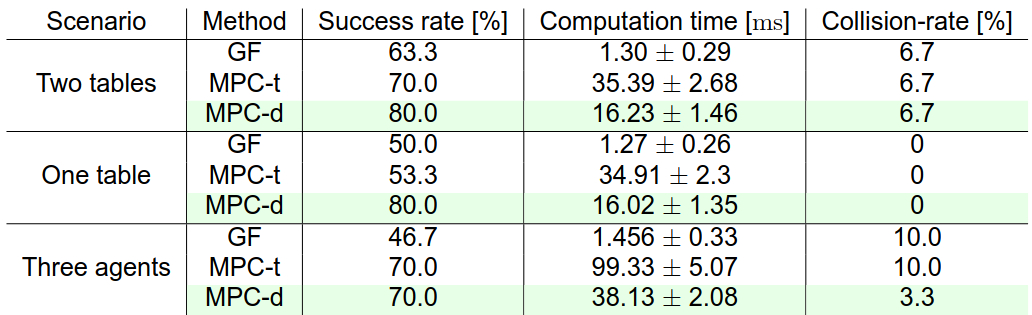

This table presents the performance of GF, MPC-d, and MPC-t across three scenarios, evaluated using metrics such as success rate, computation time, and collision rate. Specifically, MPC-d exhibits performance comparable to the state-of-the-art GF in terms of success rate and collision rate across all scenarios. Regarding computation time, although MPC-d incurs higher computational costs compared to GF, it demonstrates a significant reduction relative to MPC-t. This efficiency allows MPC-d to maintain real-time performance across all scenarios, highlighting its potential for application in real-world settings.

Real-World experiments

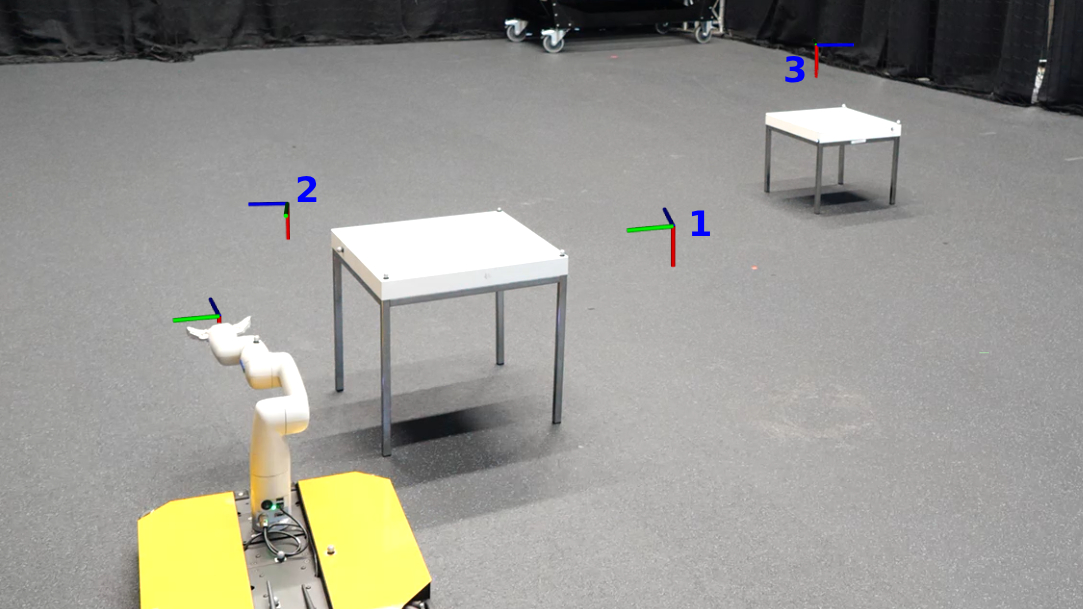

Assessing single robot static obstacle avoidance

Real-world environment for static obstacle avoidance experiments. The robot sequentially reaches three end-effector targets, indicated by the markers in the figure.

The video is played at 2x speed, illustrating how the mobile manipulator can reach three different goals without any collisions. The computation time of the MPC-d is 6 ms on average, which aligns with the results observed in the simulation experiments.

Assessing multi robots collision avoidance

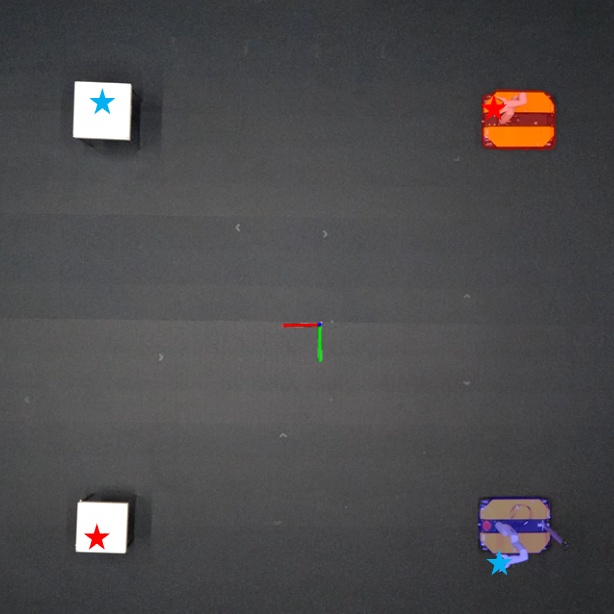

(a) Setup 1. Robots are symmetrically positioned about the x-axis.

(b) Setup 2. Robot-2 (red) is shifted 0.5 meters behind Robot-1 (blue) in x-axis

To assess dynamic collision avoidance and the effectiveness of the heuristic in resolving livelock situations, two robots are assigned end-effector targets symmetrically positioned about the x-axis, leading to intersecting trajectories, as shown above.

(a) Setup 1

(b) Setup 2

Each scenario is tested 10 times under varying start pose disturbances and other uncertainties. No collisions occur between robots and tables, demonstrating the proposed method's efficiency in real-world conditions.